8-Ton Crane Truck & Truck-mounted Crane

By chenglizhuanqi

We support custom services such as various modifications and assembly of trucks. Just contact us and let us know the type of truck you need and your assembly needs. We will provide you with your own custom truck.

Chassis Configuration:

Chengli CLW5143JSQ6SZ

Sinotruck Haoman, new 2.1m wide-row semi-widebody cab, Weichai 190hp, Fast 8-speed box, 153 rear axles, 250 three-layer girders, 825R20 steel wire tire, 4500 wheelbases, original electronically controlled air conditioner, metallic paint, all-inclusive interior, leather seats, ABS, rotary, air brake, central control door lock, electric doors and windows, remote control key.

Internal dimensions of the carriage: 5000mmX2350mmX550mm

Product Advantages:

2.1 meters wide semi-luxury cab, the widest

Weichai large-displacement brand engine

Fast 8-speed gearbox, high-torque gearbox

Aluminum alloy fuel tank, three-layer beam

Electric doors and windows, remote control key

The interior is equipped with the original air conditioner, and the cooling effect is good

The body is equipped with a 4-section straight arm crane with a weight of 8 tons from Chengli Special Automobile, with a four-way operation, radiator, and work light.

1. Introduction and main parameters of the whole machine

Chengli Zhuanqi brand KNSQ804 truck-mounted crane is a new generation of high-performance products independently developed by our company to meet the market demand and integrate many years of experience and advanced technology. The performance parameters such as lifting height, main boom length, working speed, and lifting capacity of the crane are all at the leading level.

-

The luffing, slewing, telescoping, hoisting and other mechanisms of this product are operated from the top, manually controlled, and hydraulically driven. And the crane arm head is equipped with vertical work lights, wire boxes, and other devices. And also the crane is easy to operate, flexible, stable, and reliable.

-

In the hydraulic system, there are safety devices such as a safety valve, balance valve, hydraulic lock, over-roll alarm, etc., to prevent the occurrence of accidents caused by the overload of the oil circuit and the rupture of the oil pipe.

-

The crane is equipped with complete lighting devices on the boom head and the column, which is convenient for night operation.

-

The slewing reducer of the crane is of the worm gear and worm structure, which ensures the self-locking function. The whole vehicle is equipped with slewing fixing and outrigger fixing pins, which ensures the safety of the whole vehicle when walking.

-

The design, manufacture, and quality inspection of Chenglizhuan's KNSQ804 crane meet the requirements of QC/T459 On-board Hoisting Vehicle.

1.1 Product Model:

- Model Number: KNSQ804

- Working Temperature: -15℃~40℃

1.2 Main Technical parameters:

| Item | Value | Remarks | |

|

Working Performance Parameters |

Maximum rated total lifting weight(kg) |

8000 |

2.5 meters range |

|

The maximum lifting moment of the basic arm (kN·m) |

200000 | ||

|

Maximum lifting height of the basic boom(m) |

6 |

without chassis Boom deformation is not considered |

|

|

Maximum lifting height at full extension(m) |

15.5 | ||

|

Boom lifting time(s) |

<20 |

||

|

Boom extension time (s) |

<25 |

||

|

Maximum rotation speed (r/min) |

<2.5 |

||

| Other Parameters | Weight(kg) | <2500 | |

| System Flow(L/min) | 60 | ||

| System Pressure(MPa) |

24 |

||

|

Hydraulic Tank Volume(L) |

≮120 |

||

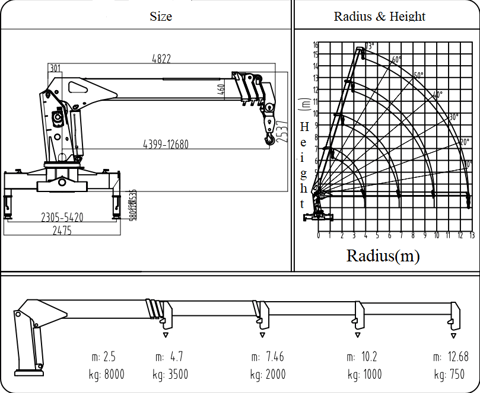

1.3 Lifting Parameters:

2. Description of each part of the crane:

2.1 Rack and outriggers:

The outrigger of the crane is an H-shaped structure. After the horizontal cylinder is fully extended, the outrigger span is 5100mm; a one-way hydraulic lock is installed on the vertical cylinder of the crane; The outriggers will not retract or fall during operation and driving; the horizontal outriggers of the crane are four-sided box-type structures, welded with high-strength steel plates with a yield strength greater than 700MPa, and a manual locking device (or hydraulic pressure) is installed on the horizontal outriggers. Locking device) to ensure that the outriggers of the crane will not be thrown out due to excessive speed when the crane is driving.

2.2 Rotary Part:

The rotation is realized by the planetary reducer driving the internal gear slewing bearing; the mechanism is mature and reliable, with a large reduction ratio and large torque; the planetary reducer has its own self-locking function, and the internal gear head is solid quenched, and tempered, which greatly improves the life of the entire mechanism.

2.3 Central rotary joint:

The outer shell of the central rotary joint is made of cast steel, the inner shell is made of steel, and nine rotary seals and two sets of guide rings are installed in the middle to ensure its durability and sealing; It is manufactured by the company in 2010, and the annual usage in China is not less than 5,000 sets, and the technology is mature.

2.4 Column:

The section of the column is a five-frame box-shaped structure, which is welded with high-strength steel plates with a yield strength greater than 700MPa. There is a circular fastening hole on the column. When the socket head cap screw at the connection between the rotary drive and the frame is loose or needs routine maintenance, the circular hole can be used to fasten the screw. This hole is usually covered by a small cover plate.

2.5 Luffing Cylinder, Balance Valve

The crane's luffing hoist adopts the traditional three-point structure. After nearly 20 years of design and optimization by our company, the mechanism is safe and reliable, and the force arm is large; the luffing cylinder is an articulated cylinder at both ends, the bottom of the cylinder, and the head of the rod. The oil-impregnated bearings are installed with powder metallurgy, which can withstand high temperature and high pressure. During use, it is necessary to add yellow grease regularly to prevent dry grinding from damaging the oil-impregnated bearings; the structure design in the hydraulic cylinder is advanced, and the common design in the crane industry is adopted. Multiple guide rings are installed on the piston and guide sleeve to increase the service life of the hydraulic cylinder; the material of the hydraulic cylinder is quenched and tempered material, which can ensure the working pressure under the condition of weight reduction.

The balance valve on the luff is a one-way balance valve, which ensures the safety of the luffing cylinder when it is used (restricts its descent) and ensures that the luffing cylinder will not vibrate when it descends.

2.6 Boom Telescopic Mechanism

The telescopic boom adopts a single telescopic oil cylinder with a pulley block to realize the telescopic boom of the boom. The boom has 4 sections in total. The telescoping of the second arm is controlled by the telescopic cylinder, and the telescoping of the third and fourth sections is realized by the wire rope installed on the boom or the cylinder. The mechanism is stable and reliable, with fast telescopic speed and high operating efficiency. The boom is lightweight, which increases lifting capacity even when installed.

A one-way balance valve is installed on the telescopic oil cylinder to ensure the safety of the telescopic oil cylinder during use (restrict its recovery) and ensure that the telescopic oil cylinder does not vibrate when retracting.

The boom head of the boom is equipped with an over-roll alarm and a vertical lighting work light. The voltage is DC 24V, which is safe and waterproof.

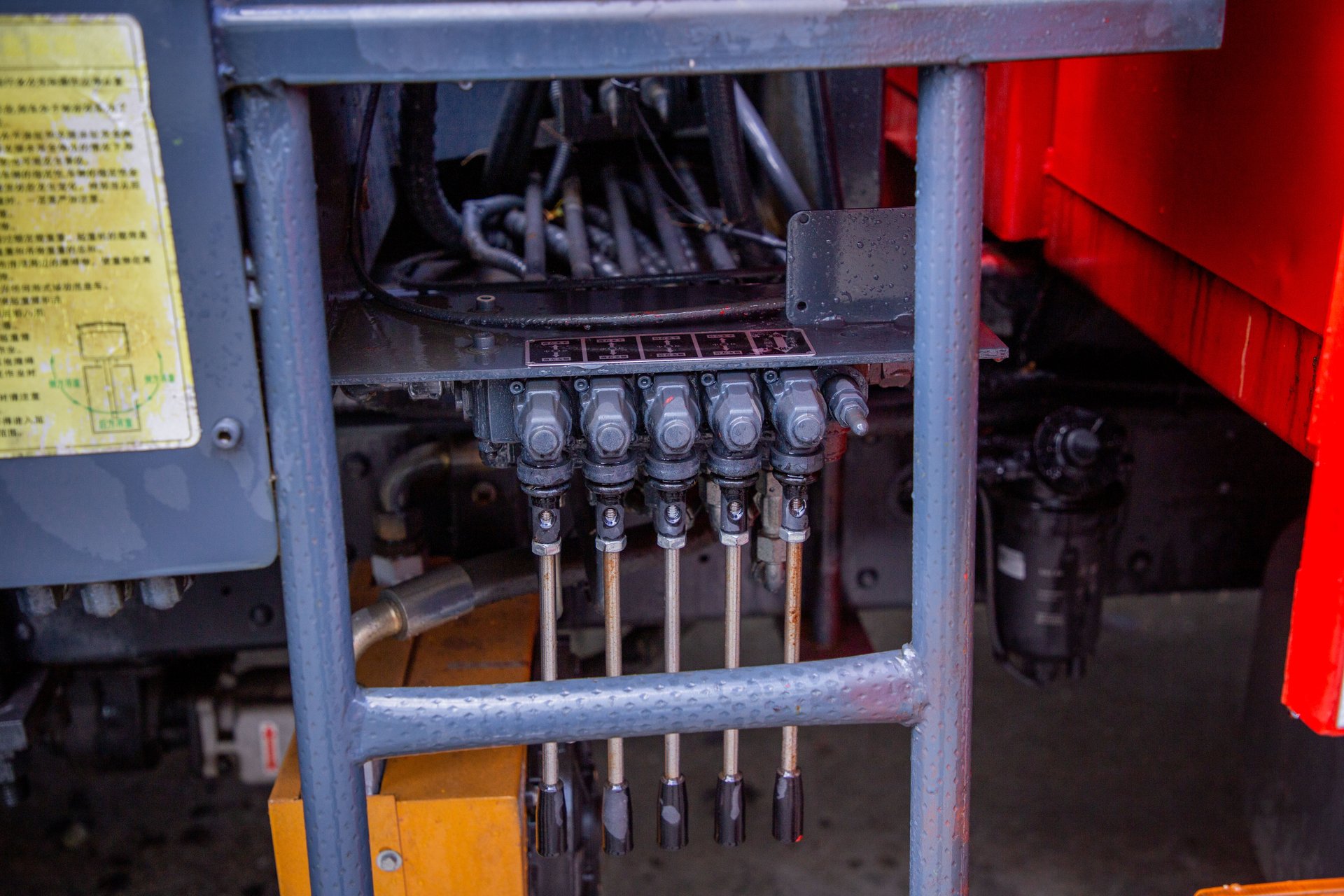

2.7 Hydraulic Multi-way Valve:

The main operating hydraulic multi-way valve adopts the multi-way valve imported from Europe. The multi-way valve has mature technology and good reliability, which can make all the movements of the crane stable and the speed controllable; the outrigger hydraulic multi-way valve adopts five control and eight control. Multi-way valve, the multi-way valve is a product with mature technology in China, and more than 2,000 sets have been tried on our company's products.

2.8 Hydraulic Winch:

The hydraulic winch adopts mature technology inside and outside. The hydraulic winch has large lifting torque and stable movement. The hydraulic winch drive motor is equipped with a one-way balance valve, which has good micro-control performance, stable braking, and low noise during use.

2.9 Auxiliary Rear Outriggers:

The auxiliary rear outrigger is a single-chamber hydraulic telescopic rear outrigger with a maximum deployment span of 3.2 meters and a height of more than 300mm from the ground, which is convenient for the crane to travel on uneven roads.

2.10 Operating System:

The main multi-way valve (mainly controlling slewing, telescopic, luffing, and hoisting) is operated in four directions, which can be operated either standing on the ground or sitting on the frame and also ensures the comfort of operation. There are many auxiliary operations. The road valve (mainly controlling the front and rear outriggers) is operated on both sides of the vehicle, which has good visibility and can prevent misoperation.

2.11 Security:

-

Warning signs are set at the pin connection of the crane, the boom head, and the rear side of the slewing column;

-

The horizontal outriggers are provided with locking devices to ensure that they will not be thrown out during driving; hydraulic locks are provided on the vertical cylinders to ensure that the outriggers will not retract or fall during operation and driving.

-

The hoisting and luffing cylinder are equipped with a balance valve so that it will not vibrate during locking and expansion; the balance valve on the cylinder has a throttling function, which can control the movement action.

-

An anti-dropping device is installed on the hook. In the driving state, the rotating part can be fixed on the base by the rotating fixing pin, which ensures safety.

Main configuration list:

| No | Part Name | Manufacturer | Remarks |

| 1 |

Multi-way Valve |

Turkey Akon Zhongmei |

|

| 2 |

Main Oil Pump |

Hebei Zhongde Hydraulic Pump Co., Ltd |

|

| 3 |

Rotary Reducer |

Tai'an Zhihe |

|

| 4 |

Slewing Bearing |

Xuzhou Saiyue Construction Machinery Co., Ltd. |

|

| 5 |

Telescopic Cylinder |

Jiangsu Tongde Hydraulic Co., Ltd. Hunan Hengli Hydraulic Co., Ltd. |

|

| 6 |

Luffing cylinders |

||

| 7 |

Horizontal Cylinders |

||

| 8 |

Vertical Cylinders |

||

| 9 |

Telescopic Balance Valve |

Yangzhou Zhongmei Hydraulic Co., Ltd./Xiangtan Ruilong Hydraulic Co., Ltd. |

|

| 10 |

Luffing Balance Valve |

||

| 11 |

Lift Balance Valve |

||

| 12 |

Hooks |

Homemade | |

| 13 |

Over-roll Alarm |

Changde, Hunan |

|

| 14 |

Hydraulic Winch |

Jining Weide Hydraulic/Taian Zhihe |

Parameters of SQ8SA3 Chenglizhuan truck-mounted crane:

|

Crane model |

SQ8SA3 (8 tons four-section straight boom) |

|||

|

Maximum lifting weight(kg) |

8000 | |||

|

Maximum lifting torque n.m |

200000 |

|||

|

Sectional Form |

Hexagonal |

Rotation Mechanism |

speed (r/min) |

2 |

|

Number of knots |

4 (extension of three knots) |

range(°) |

360(optional) |

|

|

Length (m) |

4-13.5 |

Leg |

Type | H-Type outrigger |

|

Maximum working radius (m) |

13.5 |

Span (m) |

2.3-5.7 |

|

|

Extension speed (m/s) |

7.65/30 |

hydraulic System |

System pressure (Mpa) |

22 |

|

Amplitude range |

1-72 |

Fuel tank volume (L) |

120 | |

|

Boom speed(°/s) |

76/13 |

Safety device |

Over-roll alarm |

|

|

Maximum lifting height (m) |

15.5 |

Weight (kg) |

3200 | |

|

Single rope allowable pulling force (N) |

13070 |

Matched truck |

for trucks with a loading mass of more than 9 tons |

|

|

Wire rope diameter(m) |

9.3 |

Description: The parameters in the table above are the rated parameters when the engine speed is 1500r/min. |

||

|

Wire rope length (m) |

100 | |||

Lifting Capacity Comparison Table:

|

Working radius (m) |

2.5 | 4.7 | 7.46 | 10.2 | 13 |

|

Rated load (kg) |

8000 | 3500 | 2000 | 1000 | 750 |